Industry:

3PL, Retail, CPG

Solutions:

Dock Scheduling

Driver Check-In

Documentation

J.P. Logistics is a family-owned 3PL that has been in business for nearly four decades. Founded by John O’Neill and his father in 1986 in 3,000 square feet, the company has grown to 4.4 million square feet of warehousing across Canada and the United States. With Canadian headquarters in Toronto and U.S. headquarters in Dallas, J.P. Logistics supports a wide mix of inventory for major household brands and retailers.

As volumes grew, it became increasingly important to keep yard flow, appointments, and documentation tightly aligned. J.P. Logistics began looking for a yard management and dock scheduling solution that could bring more structure to these processes and make it easier to stand behind every shipment.

They chose Conduit for its fast, plug-and-play rollout and its ability to combine dock scheduling, driver check-in, and shipment documentation in one system. In this case study, we look at how that system helped J.P. Logistics bring order to the yard, take chargebacks off their CSRs’ plates, and strengthen relationships with key retail customers.

Challenge

When Appointments Don't Match Reality

For J.P. Logistics, the pressure point was its Dallas yard. The team was moving high volumes of retail freight every day, including 10 to 15 truckloads to Walmart. Shipments had scheduled appointments, but on the ground the yard often ran first come, first serve rather than according to a plan. John described it as “literally a free for all in the yard.”

That lack of appointment discipline did not stay outside. When trucks arrived out of sequence and pushed to get into doors early, the warehouse team had to constantly react. Instead of working a clear order of operations, they were responding to whichever trailer was at the dock.

“It was causing chaos in our warehouse,” John said. “We were misshipping orders because we were just scrambling and not thinking about it.”

For customers shipping to big-box retailers, that chaos contributed to more questions and time spent compiling evidence to defend against chargebacks.

On the inbound side, the pattern was similar. “People would be showing up without appointments dropping off stuff,” John explained. “When you have, you know, 14,000 pallets in a warehouse, someone drops off three unannounced, it can get sticky.”

Too many chargebacks, too much CSR time

At the same time, J.P. Logistics was handling freight for large retailers that watch every detail. “We are shipping to all the major retailers,” John said, “and all the major retailers are always looking for ways to charge back.”

When a retailer questioned a shipment, customer service representatives (CSRs) had to pull records and assemble proof manually. Those “what happened?” calls were a regular part of the week, and chargeback research was a real drain on productivity. Before Conduit, J.P. Logistics estimates that CSRs were spending 2 hours per day researching chargebacks and related documentation for retailers that were attempting roughly $125,000 per month in chargebacks against its customers.

Together, these challenges in Dallas highlighted a clear need. J.P. Logistics needed a single system that could enforce appointments on inbound and outbound and create an accessible, trusted record for every shipment so retailers could resolve questions without long back and forth exchanges.

Solution

Choosing a system that could be implemented quickly

Once it was clear that Dallas needed more structure around appointments and yard flow, John started looking at dock and yard management solutions. He talked with several larger providers, but J.P. Logistics needed something that could be implemented quickly and without a heavy IT lift.

“We settled on Conduit for multiple reasons,” he said. “First, it was plug and play and did not take long to onboard. We were in chaos, so we needed it done quickly. From the time we started to the time we finished in Dallas, we had everybody using it within three weeks.”

Conduit gave J.P. Logistics a way to introduce real appointment control and shared visibility without a long implementation project.

Dock scheduling for inbound and outbound

Conduit became the source of truth for appointments and dock doors across both inbound and outbound. Carriers now book appointments through Conduit’s self-serve portal instead of relying on calls or informal agreements, and that schedule governs what happens when trucks arrive.

“The main thing was if you did not have an appointment, you could not just pull into a door,” John explained. “It made us control our doors much more easily, and in turn we were controlling the drivers.”

Conduit was rolled out on outbound first, where pickup congestion had been the biggest problem. After the team saw the impact, they extended it to inbound as well. Today, every inbound and outbound is scheduled through Conduit, instead of trucks just showing up whenever it suits them.

What had been first come, first serve is now shaped by a clear order of operations tied to appointments, on both the inbound and outbound sides of the business.

Contactless driver check-in and communication in one place

With Conduit, J.P. Logistics does not just have a better schedule, the team can also manage arrivals. Using Conduit’s driver check-in workflow, drivers check in from the cab using their phone and staff can see when drivers arrive, which appointments they are tied to, and whether they are still waiting or at a door.

That makes it easier to keep drivers in the right order based on appointment time, not just who pulled up first. When capacity opens up and warehouse staff want to bring someone in early, they can quickly see who is on site and ready, then reach out to them via text through Conduit’s built-in messaging rather than walking the yard or fielding phone calls.

For John, this combination of scheduling and check-in is what turned Conduit into “my police officer” on both inbound and outbound, keeping arrivals and doors aligned to the plan.

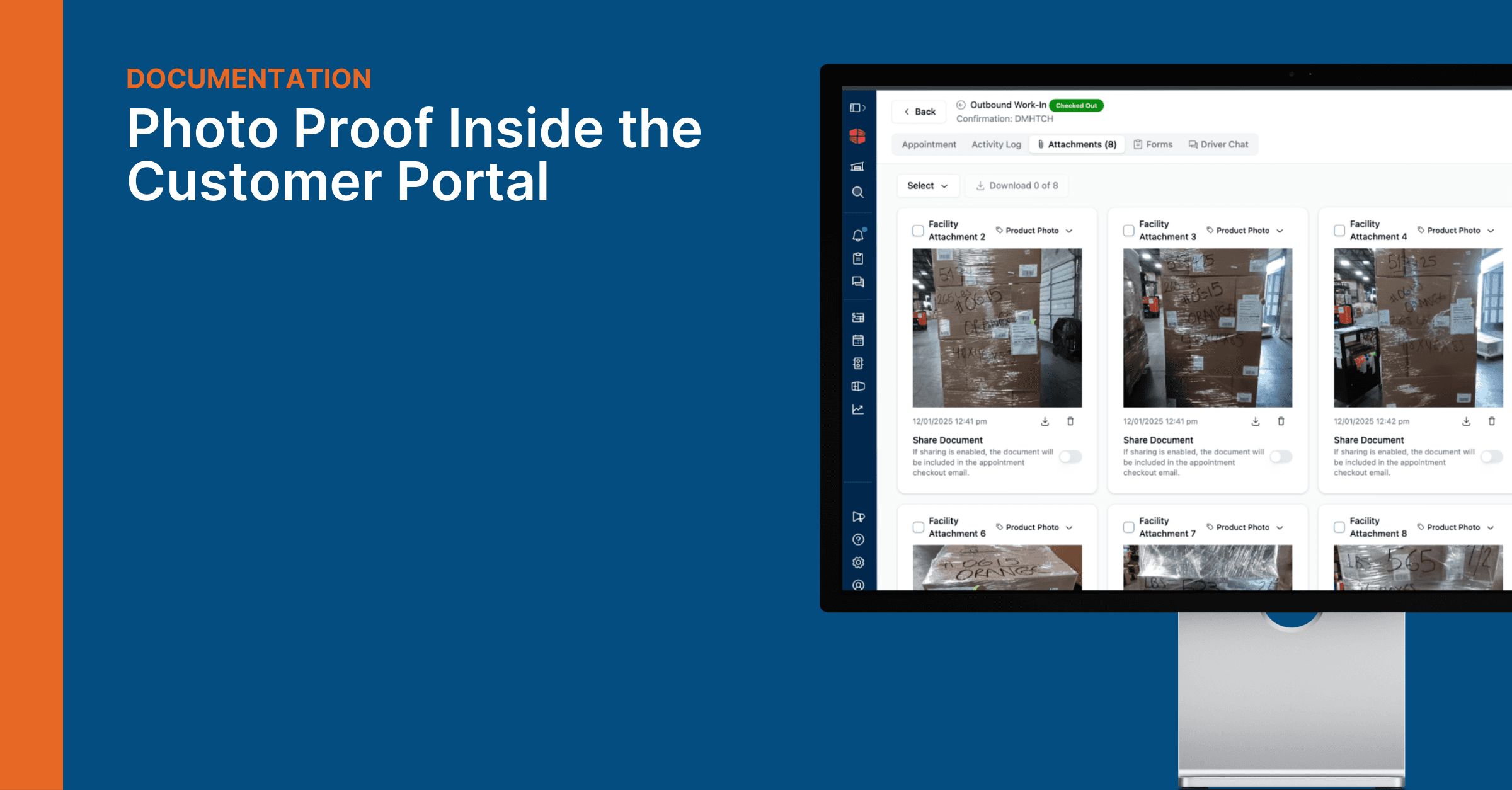

Photo-backed documentation for CSRs and shippers

Conduit also changed how J.P. Logistics handles documentation, which is especially important for customers shipping to retailers.

“We are shipping for all the major retailers,” John said, “and they are always looking for ways to charge back.”

With Conduit, the dock team can take photos of the truck and freight and upload them directly into the system, attached to the specific shipment. Those images live in Conduit alongside documents, forms, and timestamped logs for every load.

Complete shipment records are now easily accessible to J.P. Logistics’ CSRs as well as their customers via Conduit’s customer portal. This lets J.P. Logistics’ customers quickly pull the information and proof they need to defend against chargebacks, without waiting on a CSR to dig through systems and emails.

“Our calls went from 10 a week to zero because they went and got their own information,” John explained. “It completely relieved our customer service reps and got us off the hot seat for any chargeback.”

Instead of CSRs acting as investigators every time a retailer raises a question, the evidence is already organized, searchable, and shared.

Rolling Conduit out across sites

Dallas was the first site to go live on Conduit. Once J.P. Logistics saw the impact there, they rolled the system out to Toronto.

“We kicked off Dallas first and got it up and running very quickly,” John said. “Then, my Dallas team taught my Toronto team and it was easy. In less than a year, we went from nothing to having two warehouses that are much more organized inbound and outbound.”

Results

With Conduit, J.P. Logistics brought structure to yard operations that had once been “a free for all,” and built the documentation backbone their retail customers now rely on to defend against chargebacks.

The impact:

CSRs spend 90% less time on chargeback work. Before Conduit, CSRs spent 40 hours a month working on retailer chargebacks for customers: pulling records, finding photos, and answering “what happened?” questions. With timestamped, photo-backed records in Conduit, J.P. Logistics estimates that chargeback-related work is now down to about half an hour per week, freeing CSRs to focus on other priorities.

95% of documentation requests are now handled self-serve. Complete shipment records are easily accessible to J.P. Logistics’ CSRs as well as their customers through Conduit’s portal. This lets shippers quickly pull the information and proof they need to defend against retailer chargebacks, rather than asking a CSR to dig for it. J.P. Logistics estimates that 95% of customers’ documentation requests are now handled self-serve through the Conduit portal instead of via the CSR team.

A stronger 3PL partner to customers shipping to retailers. Retailers were attempting around $125,000 per month in chargebacks against J.P. Logistics’ customers. As a 3PL, J.P. Logistics does not pay those chargebacks directly, but they help customers defend against them and reduce their costs. Conduit gives those customers timestamped, photo-backed evidence they can use to defend against chargebacks, without relying on back-and-forth emails or manual digging from the CSR team.

~17 minutes saved per load. By streamlining dock scheduling, check-in, and documentation with Conduit, J.P. Logistics has made operations more efficient and eased the workload on its team.

What began as a way to bring order to the yard has become a strategic system for J.P. Logistics, pairing appointment discipline with the documentation customers need in a chargeback-heavy retail world.

Conclusion

Conduit has become part of how J.P. Logistics runs its business day to day, not just a point solution for scheduling. The team has a clear, complete picture of what shipments are coming and when, so operations feel proactive instead of reactive.

At the same time, every shipment now has a trail: photos, timestamps, and documents that customers can access on their own. That has taken most of the back-and-forth out of chargeback investigations, giving CSRs time back and making it easier for shippers to stand behind their shipments.

For customers shipping into demanding retail networks, that combination matters. J.P. Logistics can keep freight moving in a predictable way and back it up with credible proof, reinforcing its position as a 3PL that is both operationally disciplined and easy to work with.